1.4 DETERMINATION OF PARTICLE SIZE

1.4.1 Particle Size of Coarse-Grained Soils

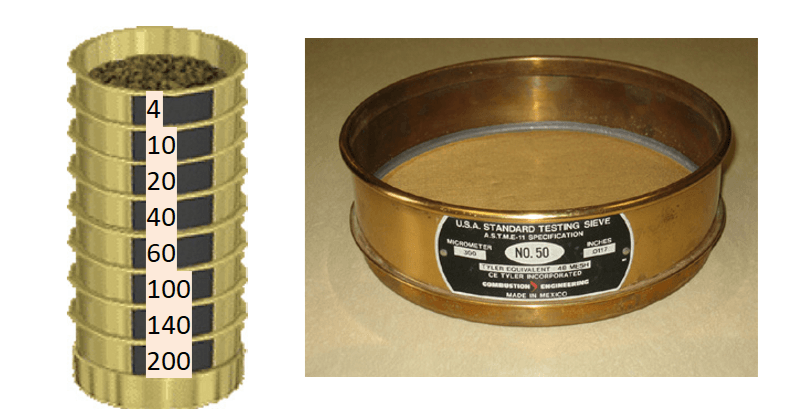

Coarse-grained soils include gravels and sands. To measure their particle sizes, a known weight of dry soil is placed on a stack of sieves with holes that get smaller from the top to the bottom (see Figure 1.6). In the United States, the sieves are identified either by a number (showing the number of holes per inch) or by the size of the opening. Other countries may use measurements in millimeters or microns.

When the soil is shaken on these sieves (a process called sieve analysis), each particle will pass through any sieve with openings larger than the particle’s own size. The weight of soil left on each sieve is measured, and the percentage of soil retained on each sieve is calculated using:

Equation (1.1)

% retained on the ith sieve = (Wi / W) × 100

Here, Wi is the weight of soil retained on the ith sieve, and W is the total soil weight.

Here, Wi is the weight of soil retained on the ith sieve, and W is the total soil weight.

The percentage of soil that is finer (passes through) the ith sieve is:

Equation (1.2)

% finer than the ith sieve = 100 – ∑(% retained on the jth sieve),

where the summation is from j = 1 to i.

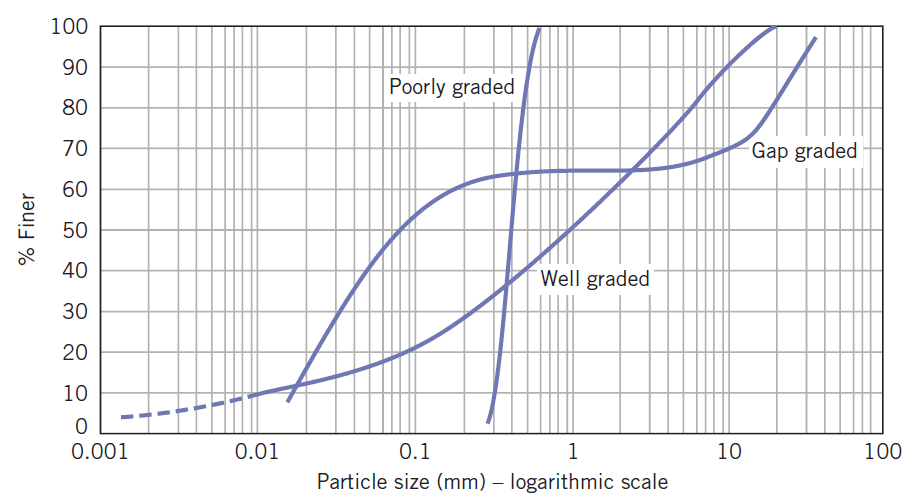

The percentages finer are then plotted against the particle sizes (on a logarithmic scale) to create a particle size distribution curve (or gradation curve), as shown in Figure 1.7. Particles smaller than 0.075 mm (those that pass the No. 200 sieve) are called fines. If a soil contains more than about 35% fines, these smaller particles can significantly affect its overall behavior.

1.4.2 Particle Size of Fine-Grained Soils

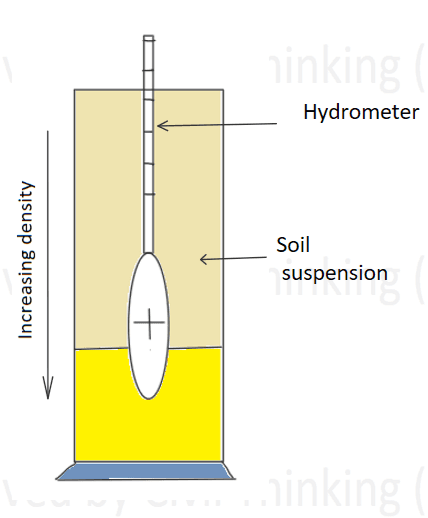

For fine-grained soils—such as silts and clays—the particles are too small to be measured by sieves. Instead, we use a hydrometer test (Figure 1.8). In this test, a small amount of dry, fine-grained soil (about 50 grams) is mixed thoroughly with distilled water to form a paste. This paste is placed in a 1000 mL glass cylinder, and more water is added until the total volume reaches 1000 mL. The cylinder is shaken well and then placed in a constant-temperature bath.

A hydrometer is inserted into the suspension while a timer is started. As time passes, larger particles settle more quickly, while smaller particles stay suspended longer. The hydrometer measures the density of the suspension at different times, and from these readings, we can calculate the diameter of the particles using Stokes’s law.

Equation (1.3)

D = √[ (30·μ·z) / (980 (Gs – 1) tD) ] = K · √( z / tD ) = K · √(vset)

Where:

- μ is the viscosity of water (0.01 Poise at 20°C).

- z is the effective depth (cm) of the hydrometer reading.

- Gs is the specific gravity of the soil particles (≈ 2.7 for most soils).

- tD is the time (in minutes) after the suspension is set.

- K is a constant that depends on μ, Gs, and temperature (≈ 0.01341 at 20°C and Gs = 2.7).

- vset is the settling velocity of the particles.

Stokes’s law assumes particles are tiny spheres that do not collide, which is not perfectly true for plate-like clay particles. Also, for very small particles (colloids), electrostatic forces and random (Brownian) motion affect settling. However, for most engineering purposes, the hydrometer test gives a good estimate of how fine-grained soils are distributed by size.

It is important to distinguish silts from clays. Apart from having different particle sizes, silts and clays also differ in strength and how they interact with water. Silts tend to have lower strength and do not absorb as much water before turning “liquid-like,” whereas clays can absorb more water and often become sticky or plastic.

More advanced methods like light-scattering tests exist for even more precise measurements, but the hydrometer test is usually enough for most geotechnical engineering needs. In Figure 1.7, a dashed line illustrates a typical distribution curve for fine-grained soils.

In summary, coarse-grained soils are analyzed using sieves to see how much soil is retained at different openings, while fine-grained soils are analyzed using a hydrometer test that measures how fast particles settle in water.

Below are the referenced diagrams: Fig. 1.6, Fig. 1.7, and Fig. 1.8.

Figure 1.6: a Stack of US sieves.

Common Sieve Sizes

| Sieve No. | Opening (mm) |

|---|---|

| 3/8″ | 9.53 |

| 4 | 4.75 |

| 10 | 2.00 |

| 20 | 0.85 |

| 40 | 0.425 |

| 100 | 0.15 |

| 200 | 0.075 |

Note: Sieve No. 3/8″ refers to a sieve with an opening of 9.53 mm.